Choosing the right epoxy floor coating for your garage or basement means understanding some common industry terms. Below, we break down key floor coating terms relevant to homeowners and businesses in Michigan.

Floor Coating Terms: Coating Types

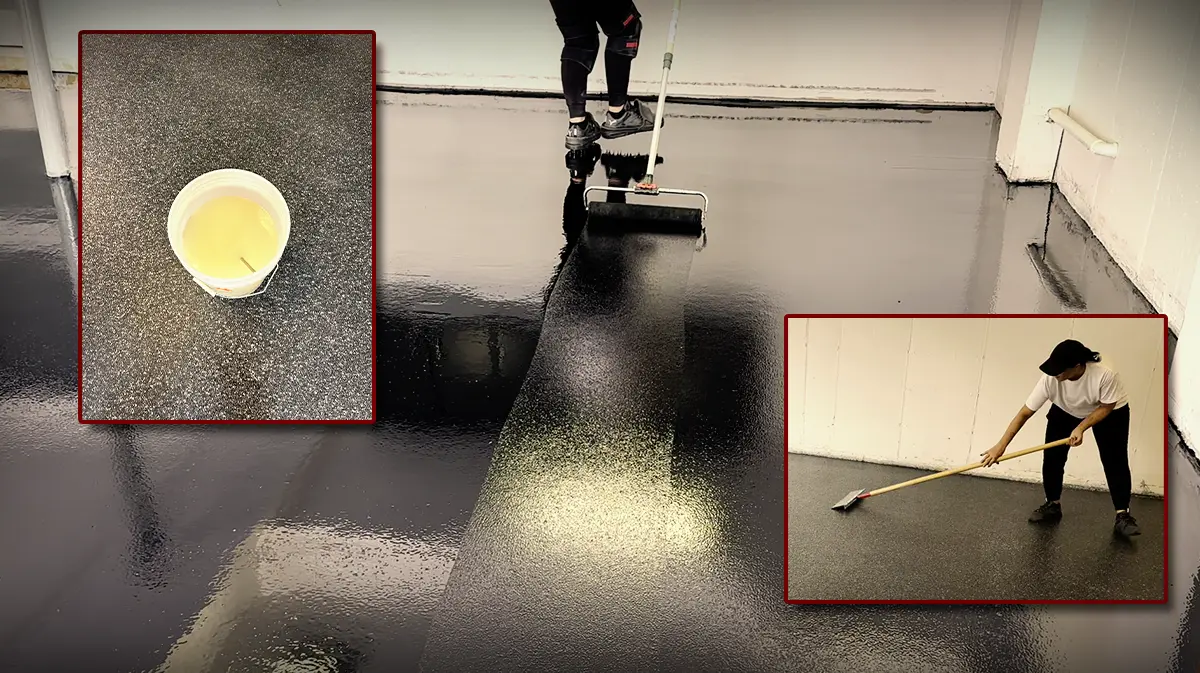

- Epoxy Coating: With Michigan’s harsh winters, an epoxy coating provides a robust solution for protecting floors against moisture wicking up through the concrete called “moisture vapor transmission” (MVT). Over time, MVT in the concrete creates a hydrostatic pressure that pushes up on the coating. Only a thick, moisture-mitigating epoxy primer (direct-to-concrete) deeply penetrates and bonds with the concrete substrate. It creates a thick, tough barrier that’s a must for garages, basements and workshops where moisture is an issue.

- Polyaspartic Coating: Polyaspartic coatings cure quickly, often within an hour. Their resistance to UV light (the sun) and chemical staining (i.e., automotive fluids and hot-tire transfer) makes these coatings ideal as clear top coats for outdoor areas or garages.

- Polyurethane: Typically applied as a topcoat over an epoxy primer, these coatings provide protection against UV, chemical spills and abrasions. Excellent for exterior installs like patios and walkways. However, polyurethanes are susceptible to hot-tire transfer (i.e., “plasticizer migration”) and are simply not meant as garage floor coatings.

Casual Terms Commonly Used in Michigan

- Garage Floor Coating: In Michigan, this term typically refers to layered epoxy or polyaspartic coatings used to safeguard garage floors from extreme UV, staining, moisture, and impacts. Garage floor coatings are easy to maintain and protect against chemical spills, wear and tear and moisture infiltration.

- Concrete Paint: Homeowners may refer to epoxy or polyaspartic coatings as “concrete paint,” but unlike traditional paint, these coatings chemically bond to the floor. Concrete paint is a less durable option that may work for light use, but it won’t provide the same level of protection as an epoxy floor.

Floor Coating Terms: Durability & Protection

- Moisture Mitigation: With Michigan’s high humidity and frequent rain or snow, moisture mitigation is key. Ensuring that water doesn’t seep up through the concrete is crucial to preventing delamination of the coating. Using moisture-mitigating epoxy coatings as the direct-to-concrete primer in basements or garages are the solution.

- Full-Flake System: A popular choice in Michigan, this system uses decorative flakes to cover the floor entirely (the flakes are “broadcast to rejection”). This flooring provides a thick, textured finish that not only looks great but provides extra durability. This slip-resistant surface is essential in wet or icy conditions, ensuring safety in both residential and commercial spaces.

Conclusion

In Michigan, having a durable, weather-resistant epoxy floor is key to maintaining the integrity of your garage, basement, or workspace. Understanding these terms will help you choose the best protective coating for your specific needs, ensuring your floor can handle everything from heavy snowfall to summer humidity. Whether it’s a basement, patio, or garage, these solutions provide the strength and versatility needed in Michigan’s varied climate.