WE’RE FIGHTING BACK: THE TRUTH ABOUT “1-DAY” COATING SYSTEMS

In a piece published in August 2020 by GarageFloorCoating.com, the potential pitfalls of “1-day” coating systems (Polyurea-Polyaspartic One-Day Systems: Do They Work) are examined. These garage floor coatings have become increasingly popular due to their quick and easy installation process which is favored by both contractors and clients alike. However, it’s important for buyers to be cautious…speed does not always equate to quality within the concrete coating industry.

What’s a Polyaspartic?

A polyaspartic is a two-component, fast-curing “aliphatic polyurea” frequently utilized in concrete coating applications. This product offers superior UV, chemical, and impact resistance once applied. If a quality 100%-solids polyurea-polyaspartic is used, it can also protect against staining from “plasticizer migration” (tire staining) caused by parked vehicles. These products prove themselves to be ideal for use as colored coats or resilient clear topcoats.

However, one major drawback of polyurea-polyaspartics is that they’re unsuitable for application directly onto concrete surfaces (as primer coats), especially when moisture is present, since they don’t bond well under damp concrete conditions. Therefore, seasoned contractors typically utilize a moisture-mitigating epoxy as the base coat followed by (multiple) layers of polyurea-polyaspartic as the finishing coats. The slower curing rate of the epoxy primer often extends installation time beyond one day.

Contractors offering “1-day” systems are aware of this fact, so they attempt to discredit epoxy products while simultaneously including warranty exclusions against “moisture-related issues”. It should be noted that all types of coatings such as epoxies, polyurethanes and polyurea-polyaspartics each hold their unique advantages and disadvantages…all these product types should feature within any reputable contractor’s toolkit.

Why Don’t “1-Day” Systems Warrant Moisture-Related Issues?

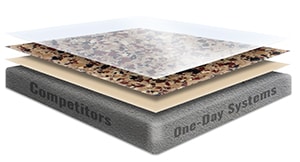

This is because these systems often apply a thin layer of (less than 100%-solids) polyurea directly onto the concrete. This approach is flawed as polyurea’s are not designed for direct application to concrete, especially in areas with medium to high moisture vapor transmission, leading to eventual delamination.

When such “1-day” coating systems fail and start peeling off, contractors conveniently invoke their warranty exclusion against “high-moisture conditions”. Many contractors promote this type of system as it requires less product and labor time which increases profitability (for them). If you’re aware that these ultra-thin “1-day” systems utilize half the required coating material, do not cover “moisture-related issues”, or tire staining (or damage from windshield wiper fluid, bleach or citrus products), then why invest in a concrete coating at all?

Us Versus Them

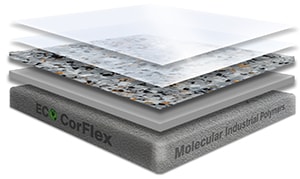

Unlike our competitors’ offerings, we provide thick garage floor coatings that come with guarantees against moisture problems and tire stains (and most car fluids). We have an extensive range of industrial-grade polyurea-polyaspartic coatings used only as top coats…two layers instead of one. They never serve as primers applied directly on concrete!

We also stand out due to our exclusive use of mica stone blends in our full-chip concrete coatings rather than just thermoplastic. As a result, our floors are thicker, stronger and visually superior. Our full-chip, mica stone concrete coatings like Bagari SE and Vintage Mica series consist of an ultra-thick 100%-solids moisture-mitigating primer coat followed by two 100%-solids polyurea-polyaspartic top coats incorporating anti-skid properties. The end result? Garage floor coatings over 35 mils thick warrantied against moisture-related issues and “hot tire transfer”, the leading causes of coating system failures.

Seeking high-end, industrial-grade full-chip garage floor coatings with a genuine lifetime warranty? Contact us or click here for your complimentary estimate.